... And, So, We Begin!

About... The background...

At the beginning...

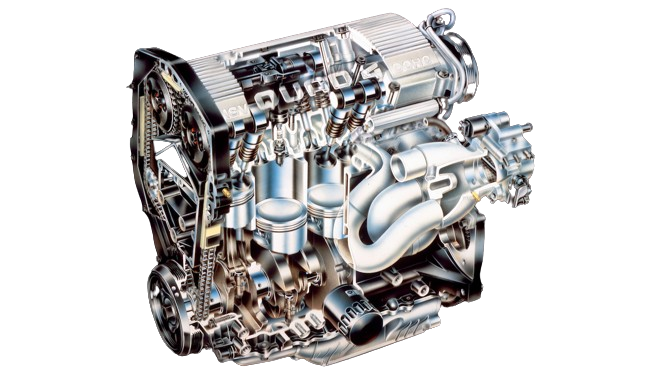

The 3.4L, as a concept, was based on a V6 version of the Oldsmobile 2.3L "Quad 4" that went into production in 1988, and which also marked the start of the GM V6 design program.

The 3.4L DOHC was the forerunner of many current motors. The Cadillac Northstar 4.6L 32 Valve V8, and later the Aroura 4.0L 32-Valve V8, were children of the V6 program. It has been expanded into the 3.5L V6 and to a degree, the OHC Truck V8 small-block.

The 3.4L DOHC motor was designed with a CHEVY badge associated with it, and was slated to go into the W-10 body cars, namely the Lumina, Grand Prix, and the Cutlass (the hero of this website). Buick opted to go with their 3800 Series I V6. Target date was 91 model year, as Lumina Z34's, Grand Prix GTP's, and Cutlass Supreme Internationals. In that order.

Gotta beef it up!...

A funny thing happened on the way to the assembly line....When it was originally concepted , the little Quad was pushing almost 200hp on 4 Jugs. So the V6 needed to have some more power. GM at that time was not known for having a good from-wheel drive transmission. Even the rocket 180 HP quads in N-body cars came with 5spds only.

No auto was offered as HI-PERF, quite frankly because they wouldn't live behind the motor (remember that they will have to warranty the car if it breaks). Well, the GM engine gurus went to their counterparts at GM's Hydramatic division with a challenge. Build a front-wheel drive auto transmission, that can handle 275 HP (the output of the said 3.4L). They gave then two years to have it in production, in a car. Hydramatic said, "no problem."

Meanwhile, the 2.8L V6 had grown to a 3.1L and was currently in use in the W-10 cars. The 3.1L was redesigned as an over-stroke version using a cast iron block. To this went the best that GM had to offer... remember, we're building a 275HP front-wheel drive muscle car with:

-

Forged crankshaft, forged rods, forged pistons, and balanced lower end...

-

Revamped oiling system with high volume pump, an oil cooler...

-

On top, a pair of computer designed 4 valve per chamber aluminum heads, with hemispherical combustion chambers...

-

Cross-Flow intake and exhaust ports, designed for maximum flow at high RPM...

Next, add

-

FOUR, count 'em FOUR camshafts, each controlling 6 sodium-filled lightweight valves.

-

Dual dampener springs rest under a "bucket" type cam lifters, for instant and precise valve timing.

-

The cams were supported by 4 journals each, providing durability along with the least amount of valvetrain mass.

-

The cams were driven by a cogged belt, further reducing mechanical drag of the motor.

-

The exhaust was cast iron manifolds, large by any standards, with a single high flow catalytic converter using 3inch downpipes. All 3.4L cars used a dual muffler system, which not by coincidence, is mathematically perfect in diameter and distance for performance applications.

-

The intake was a tuned tunnel ram, with the early builds using NO mass air flow sensor, and 94 and later ones using one.

Add to this combination Fuel injection, digital EGR, and it was by far, the BEST motor that GM engineers could build for its application. Emission certification verified an honest 281HP on the sheets. Emission 7000RPM screamer. This was in early 1990, January I believe. Transmission? Anyone?

Ooops!...

Hydramatic had its own challenges to conquer. The THM125 3-speed was being redesigned every year, to combat the next weakest link in the unit. The THM 440T-4 four speed auto debuted a few years earlier, but was prone to valve body and erratic shifting problems. The 440T-4 also had this quirk of self-destructing if the owner happened to get stuck in snow.

Not much to build from... Hydramatic had its hands full on this job. An all new FWD O/D trans was needed. Many prototypes were tested at GM proving grounds, in believe it or not, a V8 FWD Camaro. Each version had uncovered problems, aka "The next weakest link".

Time was fast running out. When it came clear that the all-new trans wouldn't be ready for production by mid-1990, there was only one thing to do. Redesign the 440-T4 as best as they could. Hydramatic went to the market with their finished product just days before the deadline.

WTF?!...

Will it take 275HP? NO! Will it take 250HP? NO! How bout 225Hp? Maybe. GM engine ground was peeved! All this effort, just to be cut down at the flywheel....225HP? I want 275! Well, the rest is corporate decision making at its worst. Cut the horsepower of the 3.4L to 200 with an automatic. You can have 210 on a stick!!

Makes a guy want to cry, don't it? Well, warranty concerns led the list of "why" and there's no way around it. The redesigned THM 440-T4 was designated the THM 4T60E, with an early RPO code of MXO. Internals were beefed up, a heavier drive chain, a better pump, and best of all, Electronic shifting!

Now, instead of a finicky hydraulic valve body, all shifts and timing ere controlled by the ECM. The same one used by the motor. Big, beefy drive-shafts were installed into the W cars to take the power. By this time, tooling up was underway for the '91 model year. While there were a supply of motors, the trans were still being built a few at a time. Delco Electronics solved the horsepower "problem" by cutting the fuel delivery and spark advance curves of the motor; this weakened it to a 6250 shift point, and 6500 rev limiter. Free-revving was limited at 3000RPM.

Production...

The first 3.4L DOHC engines were spoken for by CHEVY. After all, it was their project. Stick (manual shifter transmission) models didn't get orders, as most dealers preferred the automatic transmission models because of sales. Add to the problem, a HEFTY price tag on the motor combination, and they were a tough sell as lot inventory at the dealers.

The trans shortage had eased by Feb. of '91, and finally some units were released to Pontiac for production. These facts conclude that '91 models are scarce, some Z-34's, a lot less GP's, and virtually no Cutlass. 1992 was a carryover year for the 3.4L option. Pontiac changed wheel cap centers. This was the only visual change from the '91 cars, save the VIN of course.

Tech...

The engine used a speed-density program for the ECM/fuel injection. This consisted of a MAP sensor, a BARO sensor, ambient air sensor, throttle position sensor, and of course RPM sensor. Cubic inch displacement X rpm, barometric pressure, and air temperature divided by the throttle position and engine vacuum (load).

Without fail, the computer (ECM) will deliver the same amount of fuel for a given set of input parameters from the sensors. There is no substitute. Spark timing was calculated the same way (an algorithm) based on sensor input. This is very handy to understand when you want to modify your DOHC to do more.

The 3.4L works on a multiport injector arrangement. Early year 3.4's did not have a cam sensor in the front valve cover. These are MFI cars. The injectors are fired three at a time, with the logic that one of the intake valves will be open. The other two will puddle the fuel on top of the valve until opens. Starting in 1994, most 3.4's went to SFI.

This reduced emissions and allowed for even learn injector rates, atomization was improved. SFI basically means that the charge of fuel is fired at an OPENING intake valve, so that air flow will charge the fuel as a vapor. SFI cars are a little touchier to injector rates then MFI cars. The distributorless ignition system first added/waste spark method. It would take a volume of reference to cover it fully, but just know that it is operated from input from the crank and cam sensors.

Picture two companion cylinders (one coil pair) spark leaves the coil on one tower towards the weak cylinder, (the one on the exhaust stroke). The spark jumps the plug gap from center to ground and then travels through the engine block to its companion, (which is on the power stroke) and jumps the plug gap from ground electrode to center electrode, then back to the coil tower, completing the circuit... a big circle... it reverses every crank revolution too.

Spark timing is controlled by the ECM, which calculates which coil pair to fire, and how much timing advance or retard is needed at the moment. The intake manifold shape changed every year after 1992. Why the different manifolds? The early ones howled at 2100 RPM in drive, the later ones changed for size constraints in the car, and there was the switch to the Mass Air Flow system, which added another variant.

All will bolt to the lower intake, but not all will accept the other various equipment needed. Exhaust manifolds are pretty good for cast units. I cant even imaging fitting headers to this beast, but you don't need to. I have run backpressure gauge on my car, and found no significant problem save the converter itself. All converters are restrictive, but the exhaust is low on the list of places to get more zip from a 3.4L. And now that the background is covered, its time you get the mechanicals of the DOHC 3.4L "Hemi!"

Anatomy... Taking it apart...